| Sign In | Join Free | My fnxradio.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My fnxradio.com |

|

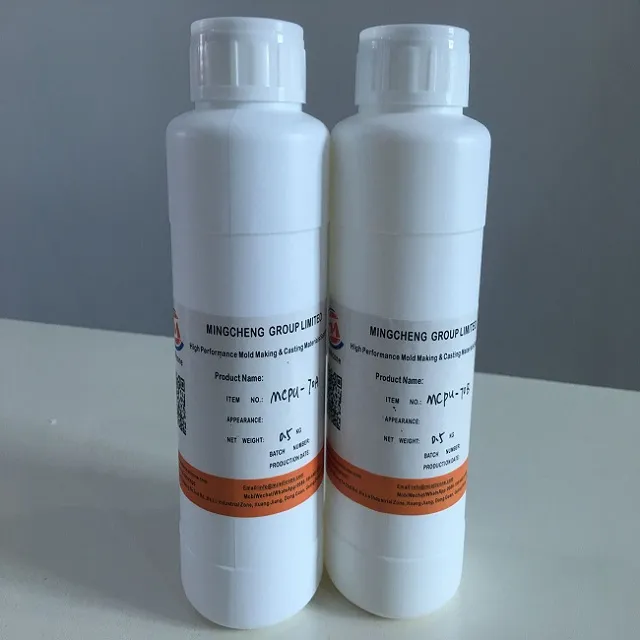

Brand Name : MC Silicone

Model Number : MC-PU80

Certification : MSDS

Place of Origin : CHINA

MOQ : 240kg

Price : Negotiable

Payment Terms : L/C, T/T, Western Union, Western Union,Paypal

Supply Ability : 4000 per day

Delivery Time : 5-8 work days

Packaging Details : 5kg, 10kg, 20kg, 200kg/ drum

Model NO. : MC-PU80

Color : Light Yellow

Hardness : 80 Shore A

Mix Ratio : 1:1

Working Time : 8-14 mins

Curing Time : 24 hrs

Tensile Strength : 18~25 MPa

Shelf life : 8-10 months

Product Description

Liquid polyurethane rubber consists of A&B component, B is curing agent, and A is polyurethane prepolymer. It can also be used as a concrete or cement stamping mold as well as for making hard durable rubber parts for machinery or automotive applications.

Characteristics:

It has excellent processing properties, solid in common temperature, shorter gel time, and regulating color by adding pigment. The ware has good properties of abrasive resistance, hydrolysis resistance, transparent, good resilience, stable dimension.

Application:

Substitute for Silicon rubber to make the mould of "cultural stone", GRC panel, concrete stamping,etc.

| A | Type | MCPU40 A | MCPU50 A | MCPU60 A | MCPU70 A | MCPU80 A | MCPU85 A |

| Appearance | Colorless or light yellow transparent liquid | ||||||

| Viscosity(30ºC)mPa·s/ | 2500±300 | ||||||

| B | Type | MCPU40 B | MCPU50 B | MCPU60 B | MCPU70 B | MCPU80 B | MCPU85 B |

| Appearance | Light yellow liquid | ||||||

| Viscosity(30ºC)/mPa·s | 560±200 | ||||||

| Ratio A:B(mass ratio) | 1:1 | ||||||

| Appearance | Light yellow | ||||||

| Operation temperature/ºC | 25~40 | ||||||

| Gel time(30ºC)*/min (variable) | 25-30 | 25-30 | 25-35 | 20-30 | 8-14 | 8-14 | |

| Hardness (shore A) | 40±3 | 50±3 | 60±3 | 70±3 | 80±3 | 90±3 | |

| Tensile strength/MPa | 4-7 | 5-8 | 5-8 | 8-11 | 9-14 | 18-25 | |

| Elongation at break/ % | 500-600 | 400-500 | 300-400 | 250-350 | 400-450 | 450-500 | |

| Tear strength/(kN/m) | 18-22 | 18-22 | 20-25 | 26-30 | 45-50 | 45-50 | |

| Rebound/ % | 30-35 | 30-35 | 30-35 | 30-35 | 36-40 | 32-35 | |

| Specific gravity(25ºC)(g/ cm3) | 1.18 | ||||||

Export pallet package

|

|

80 Shore A Liquid Polyurethane Rubber for Casting Concrete Stamp Mat Images |